|

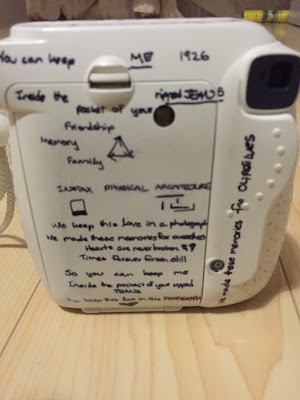

| Polaroid Camera |

Architecture Photography

Personal Interest

I decided to choose Instax mini Polaroid camera as my found object as

the camera usage in Architecture dated way back to 1385, the first architectural photograph View from

the window at Le Gras was taken by Nicephore Niepace. Buildings have

been highly valued photographic subjects, mirroring society's appreciation for

architecture and its cultural significance throughout decades. Architectural

photography usually utilized as an established visual medium. As an

architecture student, we usually refer the photographs of Iconic buildings to

study history of architecture and I love taking photographs because they always

remind me of good memories in my life that I can never go back.

But in these digital era, someone might ask 'Why Polaroid and not digital

camera?'. One big benefit of instant

film cameras is the instant gratification that they provide those who use

digital have the ability to see their pictures right after snapping them yet

they still have to go somewhere, upload, and print in order to get a tangible,

hard copy of their image. With instant film the process is far simpler, just

snap and waits for the print to shoot out the side, where it will magically

develop within just a few minutes. The images produced by instant camera film

are different from those produced by digital cameras. They have their own fuzzy, retro look, and a white

surrounding block that safely encompasses the image like a frame.

Pictures produced through instant film have a unique look that can never be

totally duplicated, as hard as online digital photo-editing applications may

try. Using an instant film camera while travelling is a great way to capture

fun, candid shots, and can give away the photos as a souvenir to new friends

you meet during the trip. The photos from instant camera have a one-of-a-kind

quality that cannot be replicate. Polaroid-style pictures make great additions

to scrapbooks. They present a small white patch at the foot of the image that

is perfect for adding the date, time, or subject's name. They also look funky

and retro, against digital and conventional prints. Taking good instant photos

requires talent and a sharp eye. There are no do-overs or edits. It is a unique

hobby that will certainly set you apart from your digital point-and-shoot

companions. Even the nicest, most-advanced digital camera cannot rival the

looks of interest and admiration that follow a person cool enough to whip out a

trendy new Fuji Instax and start snapping away.